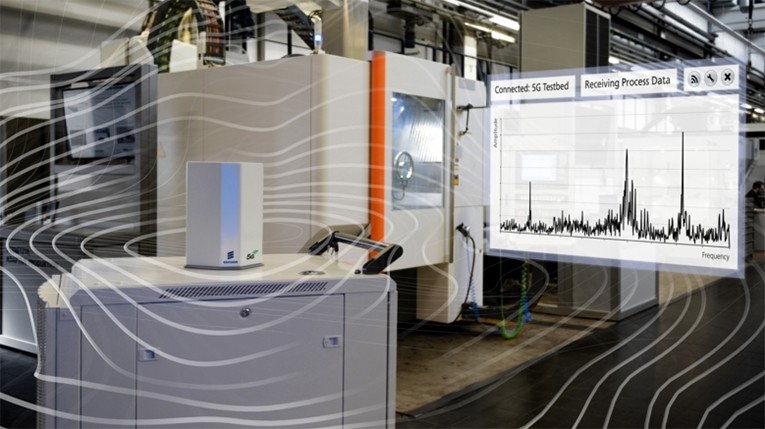

by William Leventon | Fraunhofer IPT, which researches production technology, developed the system’s wireless sensor. It is basically an accelerometer attached to a workpiece during milling, explained Niels König, the institute’s head of production measurement. (Image: Mikron MILL P 500 U Milling machine as presented at the IMTS 2018 in Chicago / The rapid data transfer allows a digital twin, the virtual reflection of a component, to be generated; Fraunhofer Institute for Production Technology)

When high-speed machining, excessive vibrations can cause unacceptable surface defects. Can 5G, the latest generation of cellular mobile communications, transmit critical machining data fast enough to slash the number of such part defects in industrial settings?

One partnership aims to find out. Fraunhofer Institute for Production Technology, Aachen, Germany, has joined forces with telecommunications firm Ericsson, Stockholm, and machine tool builder GF Machining Solutions Management SA, Geneva, to create an extremely fast-acting process monitoring system based on 5G technology.

Fraunhofer IPT, which researches production technology, developed the system’s wireless sensor. It is basically an accelerometer attached to a workpiece during milling, explained Niels König, the institute’s head of production measurement. Ericsson supplies the 5G communication technology that transmits sensor data, and GF is responsible for making the wireless sensor technology work in machine tools.

GF machines can house more than 200 sensors, but none are placed on the part being machined, noted Roberto Perez, the company’s head of innovation for digital transformation. “Sensors with wireless 5G connectivity are a new means of providing information about (part) vibration and potential defects,” he said.

According to the partners, wired sensing systems and even wireless LAN cannot meet the speed demands of this application. 5G, they say, is the only option for transmitting production data in under one millisecond, thereby minimizing troublesome latency. The goal is to allow real-time monitoring of sensor vibration data and dramatically shorten reaction times when cutting parameters need to be adjusted to prevent defects.

With its high-value components and stringent quality standards, the partners believe that the aeronautics industry may be an early adopter of 5G production technology. In this industry, any small defect is a risk, Perez said. In their battle against part defects, he said, aircraft companies spend a good deal of time and money reworking parts and incur the cost of high scrap rates.

5G technology could help. Consider the production of a blade-integrated disk, or blisk, a component of a jet engine compressor. During milling, the action of the cutting tool can cause a blisk to vibrate at its resonant frequency, König said. This produces a wavy surface, he said, which is typically dealt with by manually reworking it. In conventional blisk production, rework rates can be as high as 25 percent, the project partners report.

Using 5G technology, however, blisk manufacturers could measure critical vibration frequencies in real time and adjust the milling process when necessary—slightly increasing the spindle speed, for example. “That gets the blade out of its resonant frequency, and you get a smooth surface,” König said.

In addition to aeronautics, 5G process monitoring could help other industries with demanding surface quality requirements, including medical, automotive and mold and die. The project partners estimate that their technology could save up to $30 million a year for a single factory.

At IMTS 2018, the partners demonstrated their technology, integrating it into a live machining process to take acceleration measurements. But the current state of the technology will not do for commercial applications.

“Right now, we have quite bulky 5G transceiver systems,” König said, adding that the partnership’s current system is roughly the size of a shoebox. He thinks that the system needs to be shrank down to thumbnail size to meet industrial footprint and power consumption requirements.

Such a system might be commercially available in the not-too-distant future. “We are a research institute, so it’s not our task to deliver products,” König said. “That’s why we usually work with partners.” But after noting that San Diego-based Qualcomm Inc. has delivered the first 5G chipsets, he said, “I think it might take two or three years to have a market-ready sensor.”

William Leventon is a contributing editor to Cutting Tool Engineering magazine. Connect via phone at (609) 926-6447 or via e-mail at wleventon@gmail.com.

William Leventon is a contributing editor to Cutting Tool Engineering magazine. Connect via phone at (609) 926-6447 or via e-mail at wleventon@gmail.com.